When you’re considering the various types of gearboxes, helical gears often emerge as a strong contender due to their smooth operation and reduced noise levels. You might find that while spur gears are simpler, they can’t match the load capacity and efficiency of helical designs. Bevel and worm gears have their strengths, but they come with trade-offs that could affect your application. As you weigh these options, it’s essential to explore how each type stacks up in real-world scenarios and what that means for your specific needs.

Overview of Gear Types

When exploring gear types, you’ll often find that each serves a specific purpose in mechanical systems. Gears are vital components that transmit motion and torque between different parts of machinery.

You’ll encounter various types, including spur, helical, bevel, and worm gears, each with unique characteristics.

Spur gears, the most common type, feature straight teeth and are great for transmitting power between parallel shafts. They’re simple and efficient but can generate noise at high speeds.

Helical gears, on the other hand, have angled teeth that allow for smoother engagement and quieter operation, making them ideal for applications requiring high-speed performance.

Bevel gears connect shafts at angles, usually 90 degrees, and are often used in systems where space is constrained.

Worm gears provide a high torque output while allowing for a significant speed reduction, but they can be less efficient due to sliding friction.

Choosing the right gear type is crucial for optimizing performance and reliability in mechanical systems.

Take the time to understand their specific functions and applications, ensuring you make informed decisions for your projects.

Each gear type has its pros and cons, tailored to meet diverse engineering requirements.

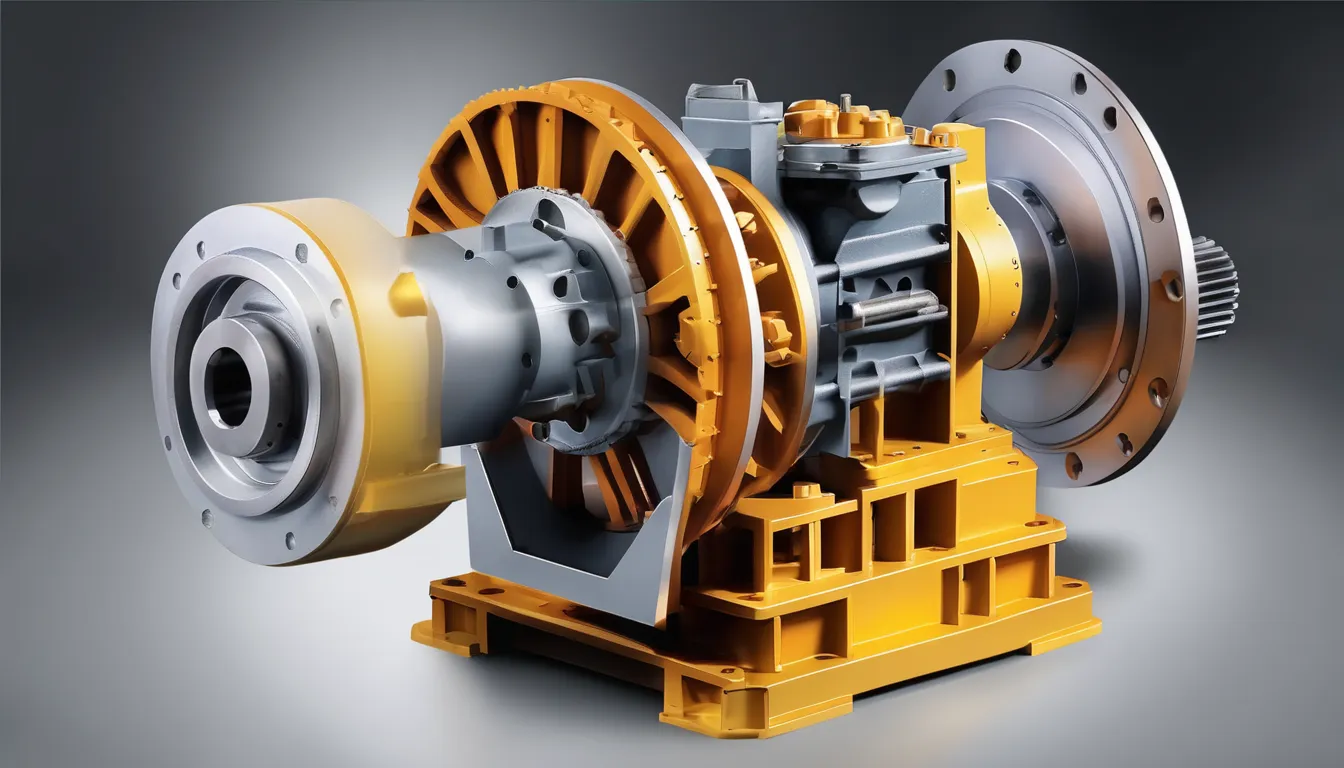

Advantages of Helical Gearboxes

Among the various gear types, helical gearboxes stand out for their numerous advantages in mechanical applications. One of the key benefits you’ll notice is their ability to transmit power smoothly and quietly. The angled teeth of helical gears engage gradually, which reduces noise and vibration, making them ideal for applications where sound levels are a concern.

Another advantage is their higher load-carrying capacity. Helical gears can handle greater loads compared to spur gears of the same size due to the larger contact area between the teeth. This means you can rely on them for demanding applications without worrying about premature wear.

Additionally, helical gearboxes offer better efficiency. Their design minimizes energy losses, allowing for more effective power transmission. This efficiency can lead to reduced operating costs over time, particularly in energy-intensive industries.

Lastly, their versatility makes them suitable for a wide range of applications, from automotive to manufacturing. Whether you need high torque or precise speed control, helical gearboxes can adapt to meet your needs effectively.

This combination of benefits makes them a popular choice in many mechanical systems.

Disadvantages of Helical Gearboxes

While helical gearboxes offer several advantages, they also come with notable disadvantages that can impact their suitability for certain applications. One of the main drawbacks is their cost. Helical gearboxes tend to be more expensive than other gear types due to their complex design and manufacturing process. Additionally, they generate more axial thrust, which can necessitate additional components like thrust bearings, increasing maintenance needs.

Another issue is noise. Although they operate more quietly than spur gears, helical gears can still produce significant noise under heavy loads. This can be a concern in environments where noise levels must be kept to a minimum.

Lastly, the efficiency of helical gearboxes can be lower than that of other gear types, especially under high loads, leading to potential overheating issues.

Here’s a quick overview of some disadvantages:

| Disadvantage | Impact |

|---|---|

| Higher Cost | Increased initial investment |

| More Axial Thrust | Additional maintenance required |

| Noise Generation | Potential disturbance |

| Lower Efficiency | Risk of overheating |

Understanding these disadvantages can help you make an informed decision when considering helical gearboxes for your application.

Comparison With Other Gear Types

Many users find themselves weighing the benefits of helical gearboxes against other gear types. When you consider bevel gears, for instance, they excel in applications requiring direction changes, but they can be less efficient than helical gears in terms of power transmission.

Helical gears, with their angled teeth, provide smoother operation and generate less noise, making them a popular choice for many users.

On the other hand, spur gears are simpler and often more cost-effective. They work well in applications where space is limited, but their straightforward design can lead to higher noise levels and less smooth operation compared to helical gears.

Worm gears, while excellent for high torque and low speed applications, have inherent efficiency losses and can create significant heat, which may require additional cooling systems.

Ultimately, your choice depends on the specific requirements of your application. If you prioritize efficiency and quiet operation, helical gears may be your best bet.

However, if cost and simplicity are your main concerns, exploring spur or bevel gears could provide the solution you need. Each gear type has its unique advantages, and understanding these can help you make an informed decision.

Applications of Helical Gearboxes

Helical Parallel Shaft Drives gearbox es find widespread use across various industries due to their versatility and efficiency in power transmission.

You’ll often see them in manufacturing machinery, where they help convert motor speed to required output speed while maintaining high torque. In automotive applications, they’re crucial for smooth shifting in manual transmissions, ensuring you get a seamless driving experience.

In the energy sector, helical gearboxes play a role in wind turbines, where they efficiently transfer energy from the rotor to the generator. Their ability to handle high loads with minimal noise makes them ideal for this application.

If you’re involved in conveyor systems, you’ll appreciate how helical gearboxes keep materials moving smoothly and reliably.

Additionally, these gearboxes are integral in the robotics sector, providing precise control over movement and speed.

In the food and beverage industry, they help in packaging and processing applications, ensuring efficiency and safety.

Conclusion

In conclusion, helical gearboxes offer smooth operation and high efficiency, making them an excellent choice for various applications. While they may have some disadvantages, their advantages often outweigh them, especially when compared to other gear types like spur, bevel, and worm gears. If you’re looking for a reliable and versatile solution for your mechanical needs, helical gearboxes are definitely worth considering. Their superior load-carrying capacity and quieter performance can greatly enhance your projects.