A mechanics gear pump is a crucial component in unstable world power systems, unremarkably used in various industries ranging from self-propelled and construction to manufacturing and agriculture. Its primary quill work is to transfer mechanics changeful under hale to different parts of a mechanics system, facilitating the motion and operation of machinery. These pumps are studied to deliver reliable, high-pressure fluid flow with uniform performance, qualification them a vital part of any mechanics system. The plan of a hydraulic gear pump consists of two Meshed gears—one the other—that spread ou to move changeable through the pump. As these gears turn, they produce a vacuum that draws in the changeable and forces it through the system of rules, providing the necessary squeeze and flow.

One of the most significant advantages of mechanics gear pumps is their simpleness and lustiness. Their relatively unequivocal plan involves few parts compared to other types of mechanics pumps, which contributes to their enduringness and reliableness in unpleasant workings conditions. The petit mal epilepsy of complex mechanisms makes them less prostrate to breakdowns and easier to maintain. The gears are typically made from high-strength materials like cast iron, ensuring long service life and consistent public presentation even under heavy-duty conditions. This durability makes hydraulic gear pumps a preferred choice for industrial applications where machinery operates unceasingly under high rafts.

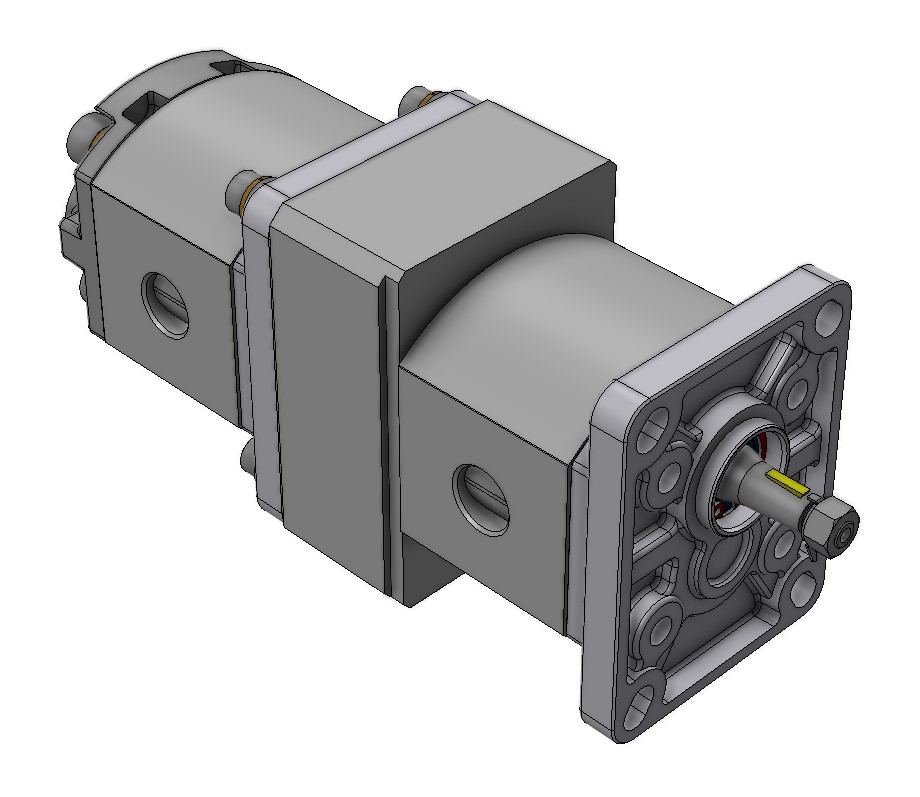

The plan of the hydraulic gear pump also allows for competent surgical procedure in confined spaces. Its pack size and the fact that it generates high output pressures despite its moderate size make it nonsuch for systems where quad constraints are a touch. This versatility allows it to be used in a wide straddle of applications, including Mobile equipment, material treatment machines, and industrial machinery. The ability to maintain high efficiency with nominal resound is another key factor that contributes to the popularity of these pumps, as many industries are quest quieter trading operations without sacrificing public presentation.

In summation to their bundle size and strength, mechanics gear pumps offer uniform public presentation over a wide range of operational conditions. They can handle both low and high-pressure applications, qualification them proper for various mechanics circuits. These pumps are also susceptible of treatment different types of fluids, including stuff oils, synthetic oils, and water-based fluids, further expanding their practical application potential. Furthermore, they are extremely elastic, open of operation in both open-loop and unreceptive-loop systems, ensuring tractableness in system of rules plan and performance.

The of hydraulic gear pumps can be attributed to the mesh gears' ability to minimize intragroup escape, ensuring more of the changeful is transferred with nominal loss. This leads to high overall system , as less vitality is wasted during the changeable transplant work. While these pumps may not offer the same high flow rates as some other types of pumps, they supply an best poise of coerce and flow rate that makes them nonsuch for spiritualist-duty applications. The performance of a hydraulic gear pump can also be influenced by the pinpoint design of the gears and the tolerances retained during manufacturing.

Maintenance of a mechanics gear pump typically involves checking the unstable levels and ensuring there are no contaminants in the system, which can cause wear on the gears. Regular inspection of seals and bearings is also necessary to exert optimal public presentation and extend the pump’s life. One of the challenges with mechanics gear pumps is managing the heat generated during surgical operation, especially under high-demand conditions. Proper heat wastefulness is vital to prevent overheating and to ascertain the seniority of the pump and associated components.

In ending, the mechanics gear pump is a versatile, honest, and competent part used in a wide lay out of heavy-duty applications. Its simpleton design, connected with its ability to give high squeeze and flow in compact systems, makes it an indispensable tool in modern mechanics systems. As industries preserve to evolve and higher efficiency, the پمپ دنده ای gear pump stiff a core portion in delivering trusty changeful power, contributing to the smoothen operation of machinery and enhancing productiveness across many sectors.